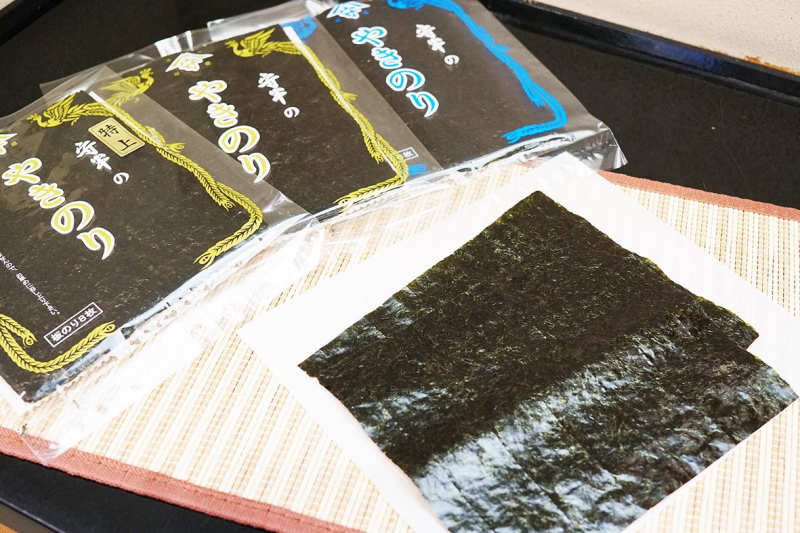

As Mr. Moriya mentioned earlier, Morihan Noriten only purchases nori from the Ariake Sea in Saga Prefecture. Furthermore, Morihan Noriten is particular about something.

“The production season for nori starts in November and lasts until March when the weather gets warmer. There are a few harvests during this time, but we only purchase nori that grows from the end of December through January. The reason for this is that the water temperature is low and the sea is rich with nutrients around this time, enabling high-quality nori to grow,” says Mr. Sato, the factory manager.

Now, just purchasing this nori and selling it is definitely not enough. Veteran artisans who know the ins and outs of nori have to perform appropriate processing in order to turn the raw nori into flavorful nori with a rich aroma. Let’s take a look at the processing procedures.

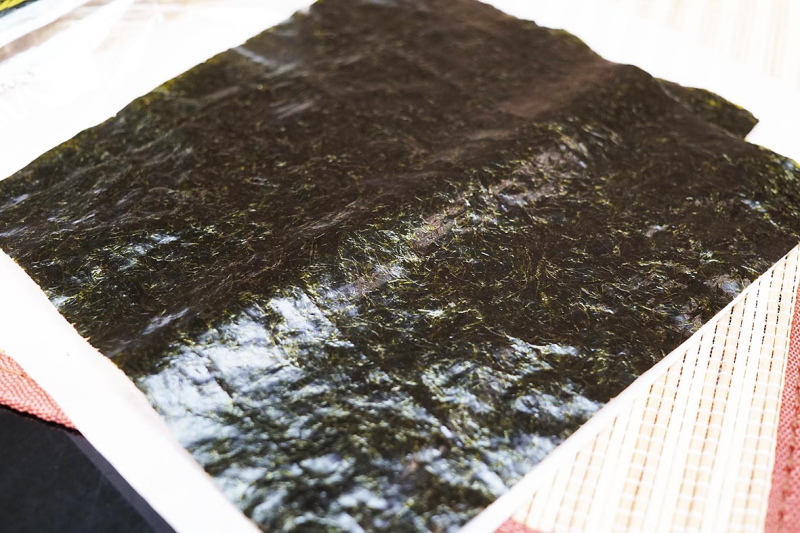

The condition of the delivered nori is soft and wavy like the above picture due to it containing lots of water. The nori is put into a dryer called a hoiro and is straightened out. Going through this process enables the nori to be stored for a long term.

Dryers for nori called hoiro

At the bottom shelf in the hoiro, there are electric heating elements so that the heat will rise up from the bottom. These days, many companies use a device that can dry the nori in a few hours, but Morihan Noriten uses these hoiro that they have been using for the past 50 years. It takes two and a half days to dry the nori with these hoiro. By slowly drying the nori, it becomes rich and flavorful.

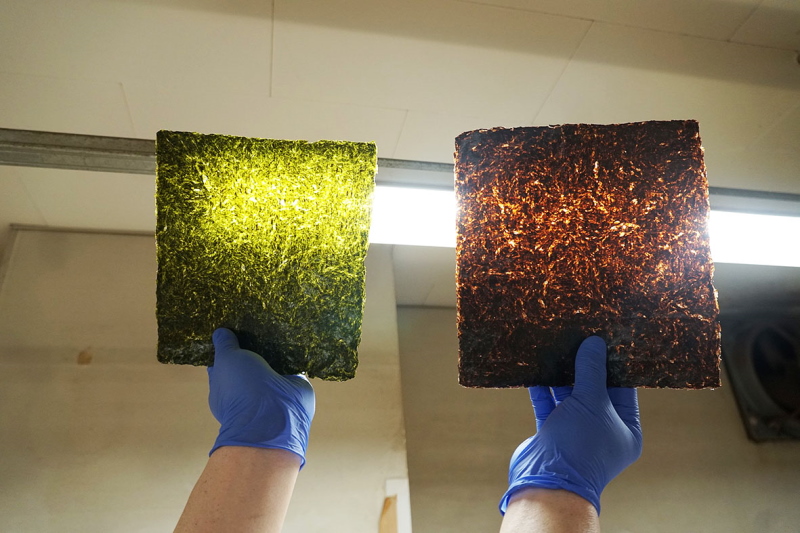

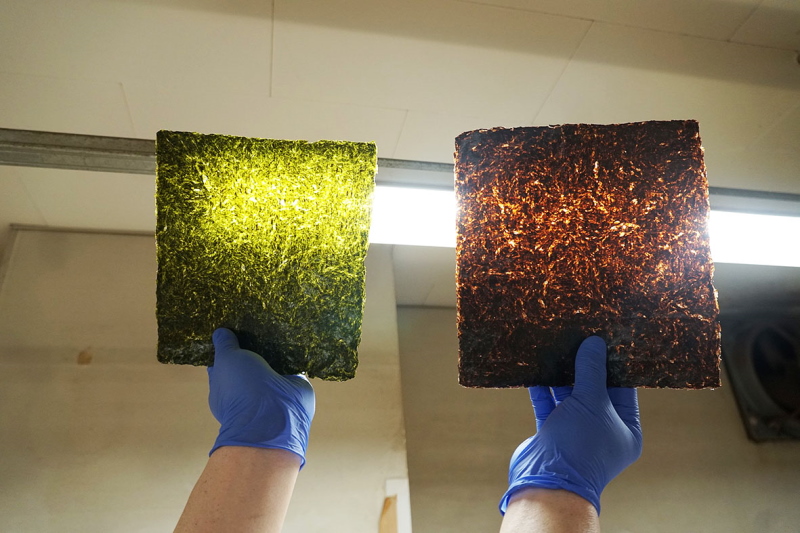

Before drying (left) and after drying (right)

You can see that the nori on the left is wavy before drying, but the nori on the right straightens out after drying, when all the water is removed.

The next step is roasting.

After drying, the dried nori becomes roasted nori by being processed in a roasting machine.

The nori is roasted carefully piece by piece in this roasting machine with a conveyor belt.

Roasting is finished in a matter of seconds, but the nori is so delicate that if the roasting temperature or time is off by even a little, it won’t become flavorful roasted nori.

This roasting machine allows the operator to fine-tune the roasting temperature as well as the belt speed, so the artisan precisely adjusts them according to the weather, season, temperature, condition of the nori, and even the humidity of the factory so that it’ll always be roasted to a certain quality. This is craftsmanship at work!

The nori on the right is before roasting, and the nori on the left is after roasting. When you hold them up to the light, you can clearly see the difference. The nori before roasting has a strong red and black tint to it, which reminds you of the color of seaweed, but the nori after roasting has a beautiful green color!

We tried both of them. The unroasted nori had a strong ocean smell and flavor typical of seaweed, but the roasted nori had a rich aroma and flavorful taste.