Ota City is widely known as a city of manufacturing, boasting the largest number of manufacturing facilities in all of Tokyo’s 23 wards, 4229*.

This special edition focuses on the origins and characteristics of Ota, the manufacturing city.

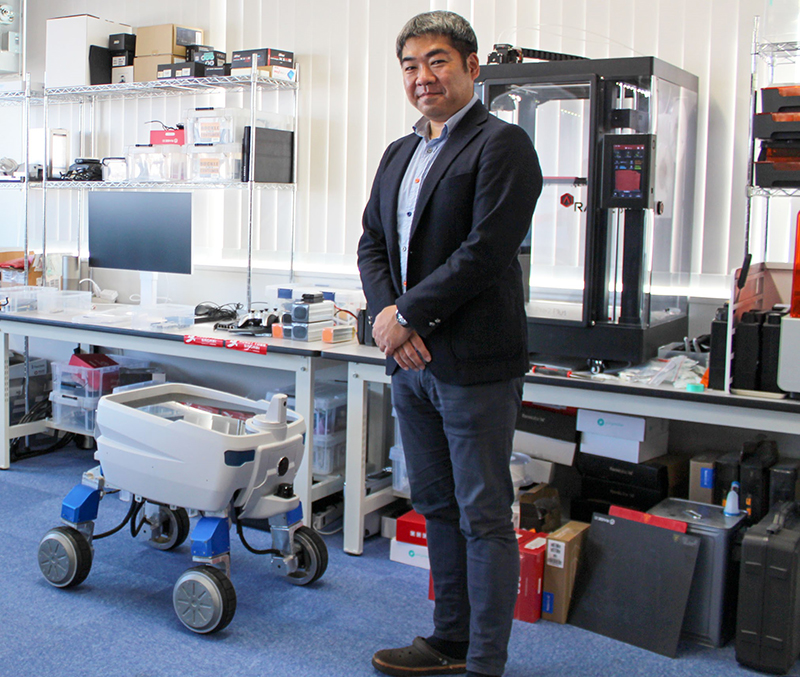

First, we interviewed Ms. Kyoko Nishikawa, Director of OTA-KOREN, which supports the promotion and development of manufacturing in Ota City.

* Source: Economic Census in 2016 (Research by the Ministry of Internal Affairs and Communications and the Ministry of Economy, Trade, and Industry)

Ms. Kyoko Nishikawa in front of Ota City Industrial Plaza PiO, which communicates industrial information about Ota City

- Please tell us why manufacturing is so prevalent in Ota City.

“The most widely known major factor was the Great Kanto Earthquake in 1923.

Many factories operating in the center of Tokyo moved to the coastal area around Ota City due to the earthquake, and these factories were used as munitions factories during the war, making the entire area flourish.

From around 1955 to 1965, the number of nori (seaweed) farms was reduced due to the harbor improvement plan, and the abandoned nori processing areas were turned into sites for factories.

It was around this time when many people started coming from other prefectures in large numbers to work at the small factories in Ota City. With time, the number of experienced people who became independent from their mentors increased, resulting in more small factories being created.”

- What are the characteristics and appeals unique to Ota City?

“Each factory site is fairly small, and half of these factories have three or fewer workers. As such, it is difficult for these factories to have an all-inclusive style, so rather than that, they tend to have unique and advanced technology that is extremely competitive.

The core technology is called fundamental technology, which is the foundation of manufacturing. It is mainly in the areas of metalworking such as cutting, pressing, molding, polishing, casting, and plating.

When parts processing is connected between adjacent factories like a relay, the best technology is brought together to create a great product. This “Nakama-mawashi” (work passed around among associates) has been a characteristic style of Ota City’s manufacturing for many years. It is sometimes called a bicycle network because the factories are located so close to one another that it is possible to get around by bicycle.

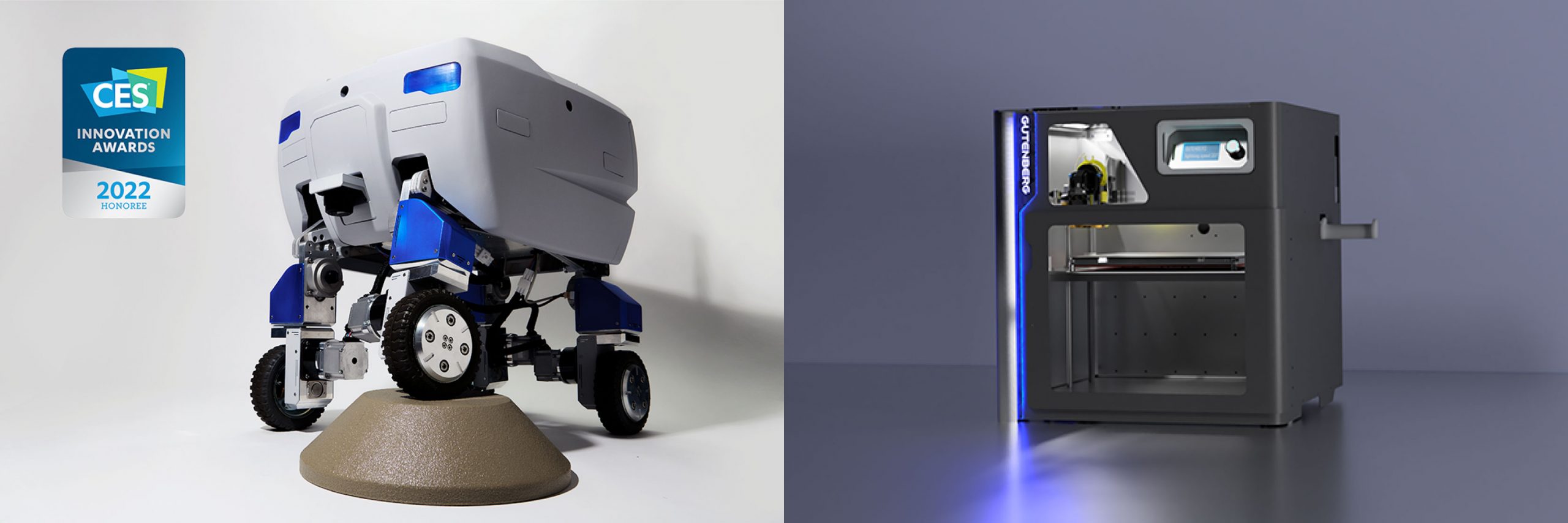

Through cooperation, even complex, high-precision processing can be completed in a very short time period. As such, manufacturing in Ota City is also highly regarded for its quick turnaround time. While mass production factories throughout Japan are shifting to Asia, small factories in Ota City in recent years have been doing high value work such as prototyping of parts for new product development.

We believe that this will progress even further, and co-creation will be in the spotlight.”

- Could you tell us about co-creation in detail?

“In other words, factories are taking the initiative. Basically, instead of a subcontracting structure in which factories wait for jobs from major companies and then work together to finish them, they are trying to create more and more jobs from the factory side.

In addition to the fact that factories in Ota City originally have the technical skills to create great products, they also have the spirit of craftsmanship necessary to produce results beyond what is required of them. By utilizing the network they have fostered up to this point, they are shifting to an innovative form of manufacturing, which is to ‘create what they want to create’ with their associates.”

- What is the difference between co-creation and Nakama-mawashi?

“If subcontracting work is passed around among associates and in the unlikely event that the order value continues to be lowered, the technical capabilities of these factories will not be properly utilized and will simply be wasted. This could lead to a decline in technology.

Rather than waiting for work to come in as they did in the past, co-creation is a concept of demonstrating the collaborative power of manufacturing in Ota City, starting from planning, proposal, development, and design, which are the starting points of manufacturing.

Beyond just the existing factories, research and development type and proposal type co-creation initiatives, which are to co-create and collaborate with industry, academia, and venture companies, are becoming more and more active.”

- Are there any efforts being undertaken to drive co-creation?

“In Ota City, we are creating a place where co-creation can be further driven by establishment of ROKUGO BASE, a business start-up support facility, and Techno FRONT Morigasaki, a factory apartment complex.

As small factories can barely take time to train their own personnel, the chronic shortage of labor is also a major issue.

In order to help them with this problem, OTA-KOREN holds manufacturing seminars to foster the next generation and provide support to help them acquire the skills essential for proposal type co-creation. OTA-KOREN cooperates with the municipal authority to hold seminars for new recruits as well. We hope that they will connect with one another as fellow workers in small factories in Ota City and that co-creation will be born from the younger generation.

The people involved in manufacturing in Ota City are all strongly committed to developing the industry as an entire community. We will continue to back up co-creation for its further development by accepting not only existing companies but also a wide range of venture companies including those from overseas in the future.”

Click here for the details of hosted seminars.

* The seminars are targeted for those who live or work in Ota City.

・Click here for the details of ROKUGO BASE, a business start-up support facility.

Now that we understood well about the origin and characteristics of manufacturing in Ota City, let’s move on to the two examples of co-creation in Ota City that we just talked about.